|

|

Post by hendrik on Sept 28, 2013 14:22:23 GMT -5

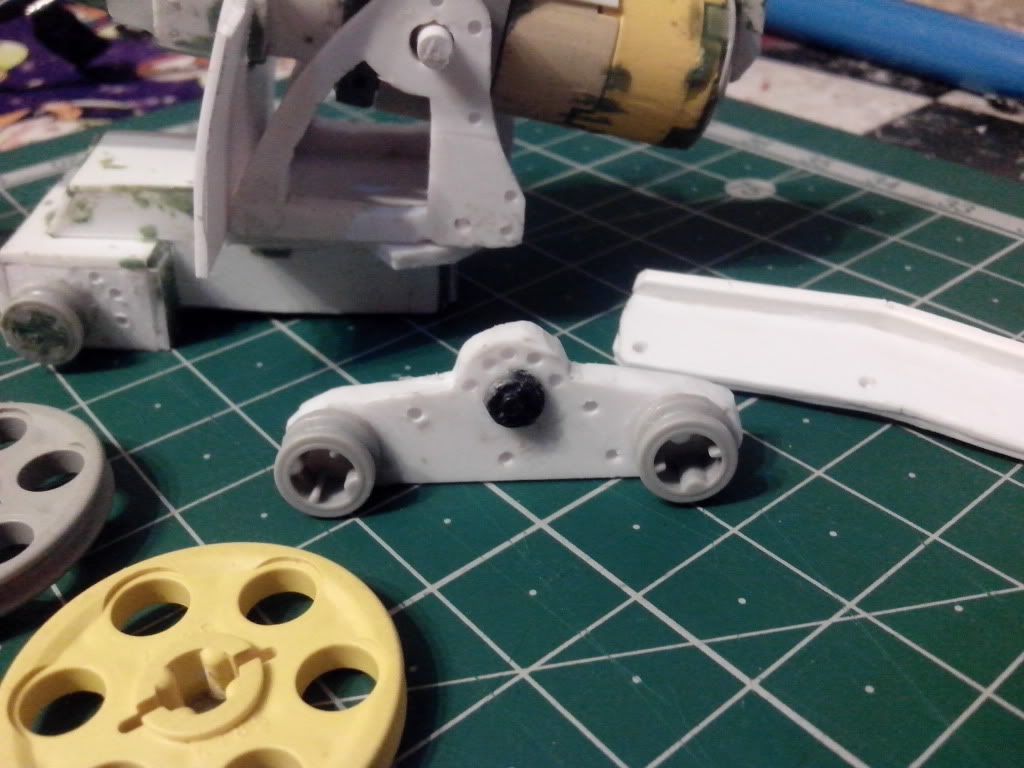

Recently I've delved into plasticard models even more and here's a collecting thread in which I will post all my plasticard works. Right now I'm working on plasticard earthshaker carriages which I intend to try to cast (since making all the parts perfectly the same is already a PITA once, I don't want to do it 8 times more! Right now all the pieces are made, and it's just clean up/correct all the mistakes before I try to make a mold of this babyboy. I've never tried making molds and casts before so that should be a challenge as well!       the other models will be cast in polyurethane. does anybody know how strong that is at a thickness of 0.75mm? since I'm wondering if casting the gunshield will work. any tips on how to cast this babyboy are most welcome! |

|

|

|

Post by BG. Foster on Sept 28, 2013 14:29:22 GMT -5

3ff3ct is your best bet for advice on casting.

|

|

|

|

Post by hendrik on Sept 28, 2013 14:41:46 GMT -5

|

|

|

|

Post by Captain Zapp Brannigan on Sept 29, 2013 22:58:44 GMT -5

Very, very VERY nice.

I love projects like these! So what models do you intend to pair this with? Any idea on the surrounding terrain for the base?

|

|

|

|

Post by 3ff3ct on Sept 30, 2013 4:10:53 GMT -5

does anybody know how strong that is at a thickness of 0.75mm? since I'm wondering if casting the gunshield will work. any tips on how to cast this babyboy are most welcome! I don't know how to express how stong it is mathematically, so I'll just have to say 'not very'. Plastic has great strength compared to resin, and at that thickness resin will crumble, even if just going in a case. A knife or something and you might get away with it, a whole gunsheild however is asking for trouble!  If you want to cast this, imagine everything is solid all the way through. It'd be really easy to cast this if you filled the main body with something on the inside and drilled in the locator holes etc. Imagine its a boat or a submarine; if water can get in, then so can silicone rubber, which is much more expensive than water and a lot harder to get out of your model withough breaking it up! It could be a simple cast of putting an extra piece of plasticard behing the places where the holes have gone  The barrel looks as if it is filled already, so that wouldn't be too difficult, same with the wheels (assuming that you attatch them to the axle afterwards). It'd be easier to fill a barrel and drill out a hole once the putty has dried, rather than trying to sculpt parts of a missing tube due to miscasts. Make sure that any bits that would need sanding/smoothing/rough edges are all dome beforehand too. Not too much of a problem with one model, however if you cast 5 of these you'll soon get sick of having to sand the areas you didn't do on your original  I'm in no means an expert, these are just things I think you could encounter,, and things that I have learnt through mistakes I've made. I might as well save you some time and effort and a few mistakes too! |

|

|

|

Post by hendrik on Sept 30, 2013 5:46:54 GMT -5

bummer! guess i'll have to make all the shields and legs out of plasticard then!(which both are easy to make though)

As long as I can cast the gunmounts and the gun itself it's all good!

I was intending to use the barrel as the opening though which I will pour the polyurethane and then drill it out indeed, inserting the thinner plasticard barrel.

Good tip about the sanding! guess i'll have to do some of that!

today I went to the paintstore to get all the materials needed for casting this, only to find out it was closed,despite their website saying they were open... bummer!

|

|

|

|

Post by 3ff3ct on Sept 30, 2013 11:42:47 GMT -5

I was intending to use the barrel as the opening though which I will pour the polyurethane and then drill it out indeed, inserting the thinner plasticard barrel Make sure the air can get out ok, otherwise you'll find some monsterous bubbles! A resin with a low viscosity should be OK though as long as you pour slowly  |

|

|

|

Post by hendrik on Sept 30, 2013 12:47:53 GMT -5

I thought pouring slowly and gently tapping the mould while it's curing were essential anyway?

I've filled up some more little gaps so will have to do some additional cleanup. do you think it's a wise idea to spraypaint the gun for another layer of gapfilling?

|

|

|

|

Post by 3ff3ct on Oct 1, 2013 3:02:07 GMT -5

I thought pouring slowly and gently tapping the mould while it's curing were essential anyway? True, although little bubbles will form as the resin cures too. In small pieces they tend to stay where they are, although in big pieces they all get together and party, potentially *&^%ing up your cast  If you have the patience, you can sit and tap it while it starts to set, or put it near the dishwasher/washing machine (although not on it!) while it's on to act as a cost effective vibration plate  I've filled up some more little gaps so will have to do some additional cleanup. do you think it's a wise idea to spraypaint the gun for another layer of gapfilling? I'm not sure as to the space-filling properties of spray paint, or how it'd react with your mold release or silicone rubber that you're making the mold with, as I've not cast anything that's been sprayed before. |

|

|

|

Post by hendrik on Oct 1, 2013 17:20:37 GMT -5

thanks for the advise! i'm now in the progress of setting up all the negatives for the molds so that once I mix up the rubber I can make all my molds at once. I hope to pour the first part of the molds tomorrow between classes, although it might have to wait untill friday.

I also went to buy the "battlefield accesoires kit" so I should be casting crates and barrels soon as well!

|

|

|

|

Post by hendrik on Oct 2, 2013 2:49:04 GMT -5

update: the casts are curing as we speak, I'll need to get some more rubber to cast the second part of the gun and gunmount but that will only happen in 24h anyway. fingers crossed this works out well!

|

|

|

|

Post by Adkenpachi on Oct 2, 2013 3:26:06 GMT -5

Fingers crossed for ya

|

|

|

|

Post by SirTainly on Oct 2, 2013 10:39:12 GMT -5

That looks great! Any plans to sell any of the castings?

|

|

|

|

Post by hendrik on Oct 2, 2013 19:13:44 GMT -5

since they are forgeworld model inspired, no. however, should the casting work fine I would highly recommend you try making your own and cast those up yourself!  |

|

|

|

Post by hendrik on Oct 3, 2013 1:26:03 GMT -5

the molds have finally cured, and here's an update on them.

-gunmold: the imprint looks really nice and it absorbed al details (rivets and plates) really well. the only thing that didn't go well are the studds that will keep both molds in place.Some water was left in the plasticine and this was remaining in the holes. overal i'm confident that the wolf will work though.

-main body: the imprint looks lovely and once again all rivets are imprinted nicely

-gunmounts:due to them being open there will be quite some mold lines, and one of the openings for the gun didn't form well, however i think they still might work

-wheelattachment: came out nicely, including all detailing

-oil barrels: came out lovely

Now i need to clean up the master again and get some more mold rubber to create the second part of the mold for the gun and main body. I can hardly wait!

|

|

|

|

Post by 3ff3ct on Oct 3, 2013 3:53:42 GMT -5

And now you're addicted  Please put some photos up then we can see the fruits of your labours! |

|

|

|

Post by SirTainly on Oct 3, 2013 4:04:34 GMT -5

Thanks, but I'm already too busy with making masters to have cast and sell through my company to have the spare time at the moment!  |

|

|

|

Post by hendrik on Oct 3, 2013 11:33:39 GMT -5

I've yet to make the second part of the gun and main body cast, but if everything goes well I might have my first cast piece by monday!

|

|

|

|

Post by hendrik on Oct 4, 2013 11:25:04 GMT -5

update-ish, I just got the casting material, however i'm too knackered to try and finish the mold after partying last night and discovering they towed away my van when i wanted to drive home...

which makes me think of atlas recovery vehicles....

|

|

|

|

Post by hendrik on Oct 5, 2013 16:19:43 GMT -5

so, 24 hours have passed and the molds should have been ready. but when i removed some of the molds from their container it seemed the rubber had not set yet! :s has anyone had this happen before? I mixed the whole batch for quite a while so both compounds should have been mixed together quite well... I'm not leaving the molds to dry for another 24 hours. hopefully by then they will have set :s

|

|

|

|

Post by hendrik on Oct 7, 2013 5:23:41 GMT -5

|

|

|

|

Post by BG. Foster on Oct 7, 2013 5:53:29 GMT -5

Not seeing any pictures.

|

|

|

|

Post by hendrik on Oct 7, 2013 6:17:08 GMT -5

here it's working fine and a friend of mine could see them too :s

|

|

|

|

Post by BG. Foster on Oct 7, 2013 6:20:01 GMT -5

I can see them now, must have been my internet at the time.

|

|

|

|

Post by hendrik on Oct 11, 2013 7:30:37 GMT -5

|

|